Post Image

Image

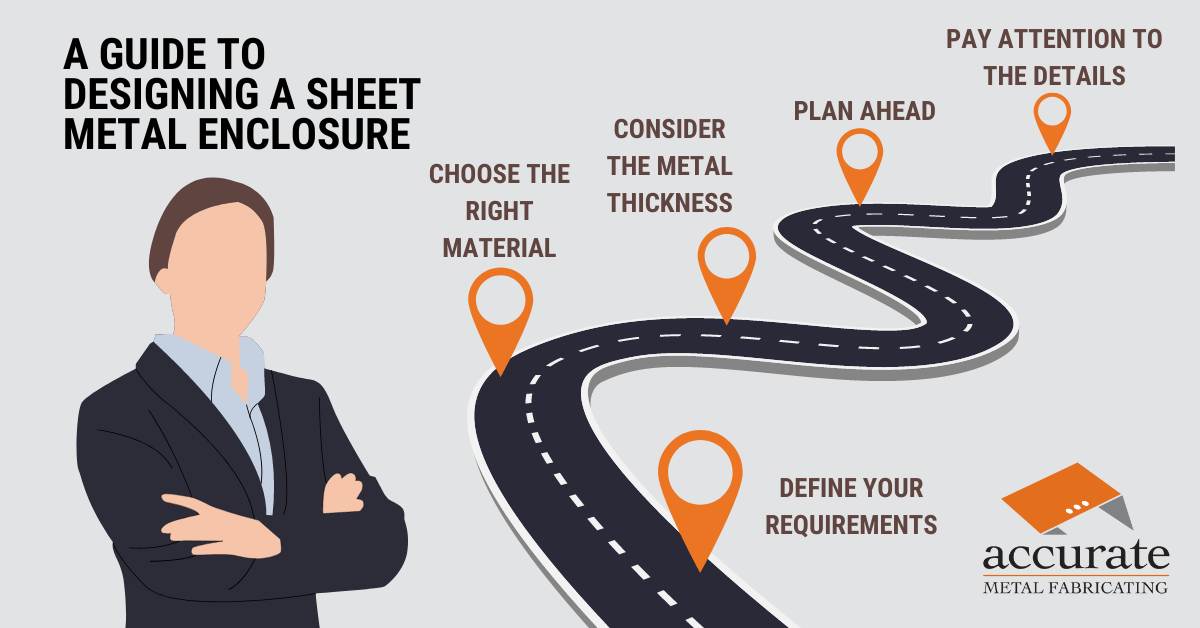

Designing a sheet metal enclosure is about far more than creating a metal box. A successful enclosure must protect internal components, manage airflow, support installation and serviceability, and withstand real-world conditions over time. Each decision—from material selection to fabrication methods—directly affects performance, cost, and manufacturability.

At Accurate Metal Fabricating, we partner with OEMs and engineers throughout the process of designing a sheet metal enclosure, helping transform early concepts into production-ready solutions. This guide outlines the key considerations for reliable, efficient enclosure designs.

Step 1: Define the Application Requirements

Before beginning the design, clearly define the enclosure's requirements. Dimensions, internal components, access points, mounting requirements, and environmental exposure all influence the final design.

Enclosures used indoors may prioritize appearance and accessibility, while outdoor or industrial enclosures must account for moisture, temperature swings, vibration, or chemical exposure. Providing this information early helps your fabricator recommend the right materials and design features while avoiding costly changes later.

Step 2: Choose the Right Material

Material selection plays a significant role in enclosure performance and cost.

Carbon steel is commonly used for indoor applications due to its strength, affordability, and excellent paint adhesion. It is ideal when corrosion exposure is minimal, and a durable painted finish is desired.

Aluminum offers a strong strength-to-weight ratio and natural corrosion resistance, making it well-suited for portable enclosures and outdoor applications. While aluminum typically costs more than carbon steel, it allows for lighter designs without sacrificing performance.

Stainless steel provides superior corrosion resistance and a clean, professional appearance. It is often specified for harsh environments, public-facing installations, and applications requiring long-term durability. Although it incurs a higher material cost, stainless steel excels when reliability and appearance are critical.

A qualified fabricator can help weigh these trade-offs during the early stages of designing a sheet-metal enclosure.

Step 3: Consider Sheet Metal Thickness

Sheet metal thickness affects strength, rigidity, and overall weight. Thicker material increases durability but adds cost and weight, while thinner material reduces weight but may require additional reinforcement. Often, strength can be achieved through smart design rather than heavier material. Features such as bends, flanges, and formed returns allow thinner gauges to perform effectively while keeping the enclosure efficient and cost-conscious.

Image

Step 4: Design for Manufacturability

Sheet metal enclosures are produced using processes such as laser cutting, punching, forming, welding, and assembly. Designing with these processes in mind helps control costs and lead times. Simpler bend patterns, consistent hole spacing, and reduced part counts improve manufacturability. During this phase, collaboration between engineering and fabrication teams is critical. Early feedback can prevent unnecessary complexity and streamline production.

Step 5: Incorporate Structural Features

Structural features strengthen an enclosure without adding excessive material. Flanges, ribs, gussets, and formed channels increase rigidity and help support internal components. Mounting rails or brackets can also be integrated to simplify installation and maintenance. These details are especially important when designing a sheet metal enclosure intended for frequent access or for heavy internal equipment.

Step 6: Plan for Ventilation and Thermal Management

Enclosures housing heat-generating equipment require proper airflow. Vent patterns, louvers, or perforated panels allow air to circulate and prevent overheating. In some cases, fans or conductive heat-dissipation features may be required. Thermal management should be addressed early in the design process, as retrofitting ventilation after fabrication can be costly and inefficient.

Step 7: Address Sealing and Gasketing

When an enclosure must resist dust, moisture, or air leakage, sealing becomes critical. Gasket channels, welded seams, and proper fastening methods help protect internal components and maintain reliability. Attention to sealing details ensures the enclosure performs consistently under pressure and in demanding environments.

Designing A Sheet Metal Enclosure with Accurate Metal Fabricating

Designing a sheet metal enclosure is most successful when engineering, fabrication, and finishing are integrated. Accurate Metal Fabricating offers in-house laser cutting, forming, welding, powder coating, and more. It is all supported by experienced project managers and engineers.

From concept to production, we help ensure your enclosure meets performance requirements, manufacturing standards, and delivery timelines.

Contact Accurate Metal Fabricating to start designing your next sheet metal enclosure with confidence.