Our metal degreasing line delivers material faster than before. At our sister company, Accurate Perforating, located at 3636 S. Kedzie Ave in Chicago, we no longer need to send the perforated material to a 3rd party for degreasing. We can move material from the levelers to the degreasing line, with no delay and often reducing lead time by a week or more.

Why Would You Need A Metal Degreasing Line?

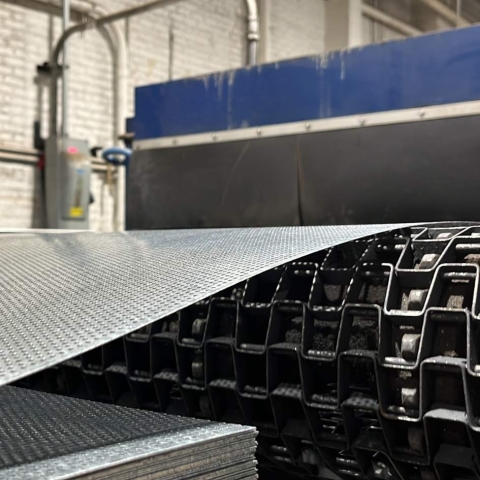

During manufacturing, perforated metal components often pick up grease or other oils. To protect the equipment, lubricants are applied before punching as the metal passes through the press.

Therefore, custom metal degreasing services are necessary to prevent complications from residual contamination. Grease can interfere with coating application and cause imperfections in precision parts.

Fortunately, our metal washing line ensures parts are clean and in optimal condition. And we can "toll process" your parts on it. Just ship your material to our facility, provide us with the date you need it, and we'll take it from there!

Contact Us

What Can You Run through A Degreaser?

- Perforated Sheets

- Solid Sheets

- Perforated Metal Coils

- Solid Metal Coils

- Formed Perforated Sheet Metal Parts

- Formed Solid Sheet Metal Parts

- Outside Parts and Components, including stamped, cast, machined, and welded material

- Parts with Protective Coatings (e.g., blue)

- Plastic Material

Max Specifications

- Maximum Width: 60"

- Maximum Height: 12"

- Maximum Length (Sheet): 20'

- Maximum Width (Coil): 60" Wide

Choose Accurate For Your Metal Fabricating Needs

Degreasing is just one of the many services we provide. Our comprehensive capabilities enable you to complete virtually any high-volume metal fabrication project on time and to your specifications. We can, in most cases, help you engineer parts. Contact us today to learn more about how we can support your operations.