Powder coating offers significant advantages for protecting and enhancing metal parts. More durable than liquid paint, it creates a finish that resists wear, weather, and corrosion while allowing flexibility in color and texture. For OEMs, architects, and product designers, the powder coating advantages come down to performance, consistency, and long-term value.

In this article, we'll explore five key advantages of powder coating that extend product life, improve finish quality, and reduce long-term maintenance costs.

1. Durability

A properly cured powder coat resists chipping, cracking, peeling, fading, and corrosion. For exterior and high-demand projects, finishes that meet AAMA 2604/2605 standards deliver proven performance in terms of humidity, salt-spray resistance, color retention, gloss, and chalk resistance. This makes powder coating ideal for outdoor equipment, architectural elements, and enclosures.

2. Versatility

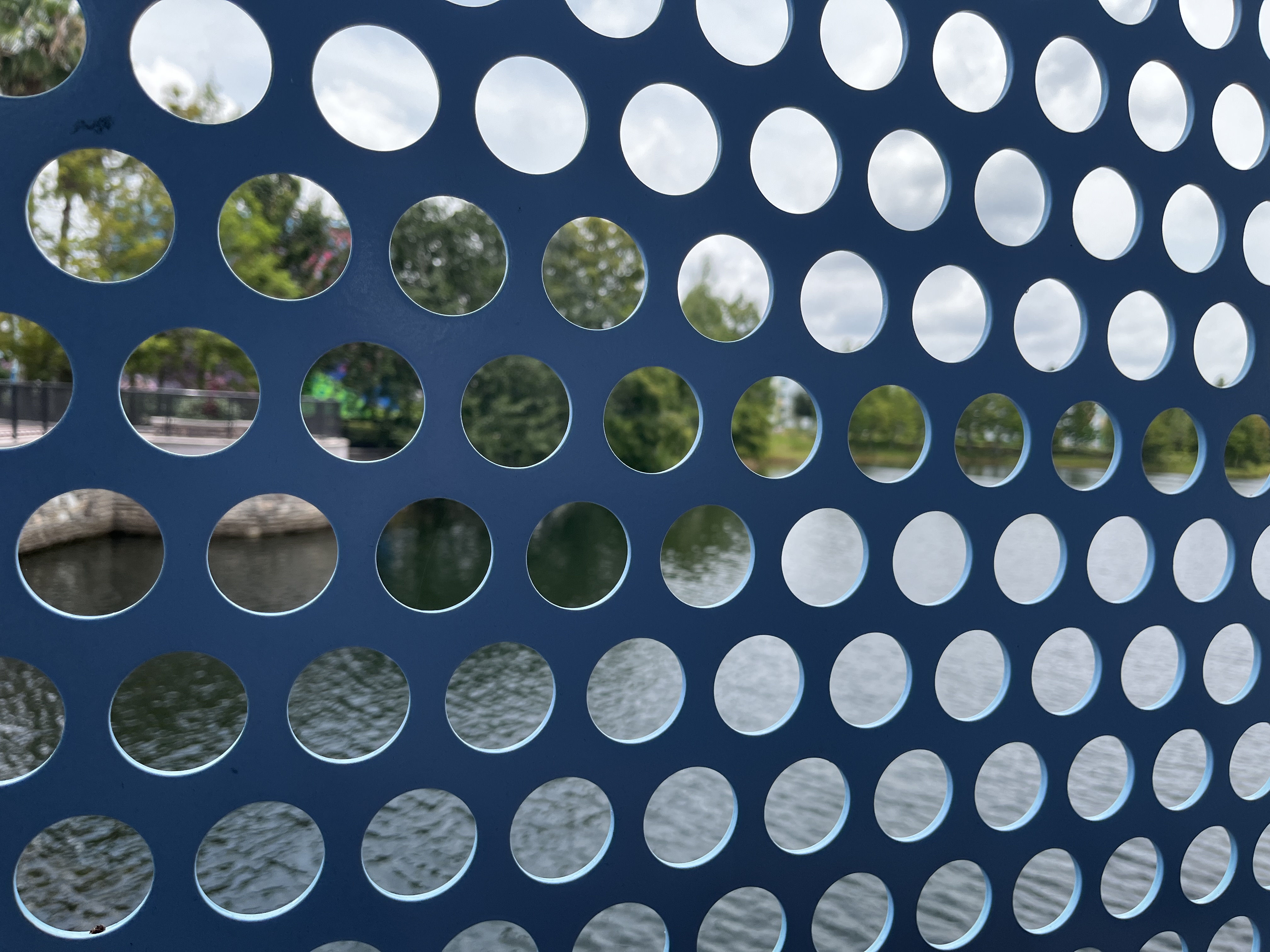

Powder coating is suitable for use on steel, aluminum, and other standard alloys. You can specify brand-true colors using RAL or Pantone matching and select textures ranging from smooth to matte to fine-structured. This flexibility supports both decorative and functional applications, including POP displays, cable-management racks, and perforated architectural facades.

3. Environmentally Friendly

Powder coating contains no VOCs and is engineered for material recovery, with overspray reclaimed and reused. Surface prep water is treated and recycled to maintain the proper chemical balance, supporting consistent adhesion and finish quality while minimizing environmental impact.

4. Cost-Effective

Continuous lines and fast changeover enable efficient runs once parts are fixtured, helping you control application time and total cost. Because powder-coated parts last longer and require less frequent refinishing, you also reduce maintenance and downtime over the equipment's life.

5. Consistency

The electrostatic charge attracts powder to the substrate, providing even, wrap-around coverage and a smooth, drip-free film after curing. With in-line quality checks and process controls, you get repeatable color and gloss from lot to lot, which is critical for multi-site programs and long-running SKUs.

BONUS! Ease of Maintenance

Powder-coated metal surfaces are easy to clean and maintain. The metal is scratch- and stain-resistant and can be cleaned with mild soap and water.

What Powder Coating Advantages Does Accurate Have?

-

AAMA 2604/2605 capable finishes for demanding environments

-

5-stage wash pretreatment for adhesion and corrosion protection

-

Color matching via RAL or Pantone

-

All standard powder chemistries, including epoxy, polyester, and zinc-rich primer

-

Part capacity up to 4' W × 6' H × 10' L, 400 lb with automated line application and in-process quality control

Ready to Extend the Life and Look of Your Metal Parts?

The advantages of powder coating are clear: durability, versatility, environmental benefits, cost savings, consistency, and easy maintenance. At Accurate Metal Fabricating, we combine precision fabrication with advanced powder coating to deliver finishes that not only look great but also perform.

Contact Accurate Metal Fabricating today to discuss your next project and see the difference a high-quality finish can make.